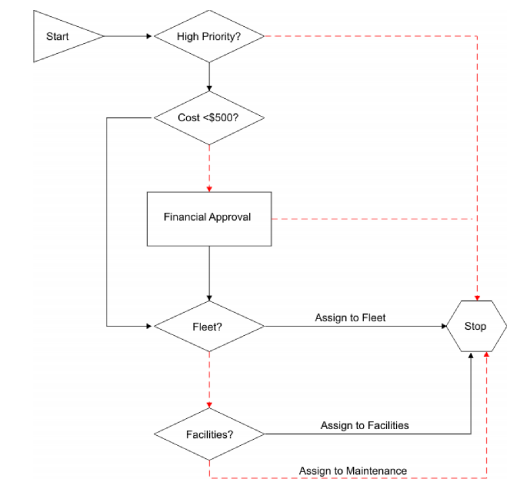

A workflow process can be created to handle a work order. An enterprise has configured the system to route all new preventive maintenance work orders that are generated through the Phoebus Scheduler, which is automatically run at server.

The first step is to evaluate the priority of the work order, as follows:

If the preventive maintenance work order is high priority or has a null value in the Priority field, it is routed to a work planner for immediate review and approval.

If the preventive maintenance work order has a low priority, it is routed to a Stop node and exits the process.

All preventive maintenance work orders then go through a financial approval process. Work orders with an estimated total cost of less than $500 are automatically approved. The maintenance supervisor must review and approve work orders with an estimated total cost of more than $500.

After a work order passes the financial approval process, it must be assigned to awork group, as follows:

❑ If the preventive maintenance work order is for a vehicle, the system assigns it to the fleet maintenance group.

❑ If the preventive maintenance work order is for a building or location, the system assigns it to the facilities maintenance group.

❑ The system assigns all other preventive maintenance work orders to the maintenance group.

After the system assigns the work order to a maintenance group, the work order exits the workflow process.

The following diagram illustrates one way that you might map the preceding scenario.